Quality frame fabrication for window, doors and commercial projects.

Our team, composed of skilled technical experts, is dedicated to creating frames that are not only structurally sound but also aesthetically pleasing. Every stage of the fabrication process is approached with a meticulous eye, ensuring that each frame meets our high standards of quality and durability.

Our journey in frame fabrication begins with the selection of premium materials, chosen for their longevity and adaptability. From the initial design phase to the final touches, our team collaborates closely, ensuring that every aspect of the frame reflects our dedication to excellence. This collaborative environment fosters innovation and allows for a seamless integration of traditional techniques with modern technology.

Take some time to learn more about our manufacturing processes and how our team will create your bespoke doors, windows and frames.

Get started with a free quote

1. Specification & Materials Sourced

The initial stage of frame fabrication begins with a thorough review of the specifications provided by the client. Precision is paramount at this stage, as our team meticulously checks and rechecks the measurements to ensure that every detail aligns perfectly with the client's vision. This careful scrutiny sets the foundation for the entire fabrication process, guaranteeing that the final product not only meets but exceeds expectations.

Following the verification of specifications, we move to the critical task of sourcing materials. Our commitment to quality drives us to select only the finest materials, tailored to suit the specific requirements of each project. We engage with trusted suppliers to procure materials that promise durability, aesthetic appeal, and compatibility with the design. This careful selection process ensures that the frames we produce are structurally sound and align with the environmental and aesthetic standards of our clients.

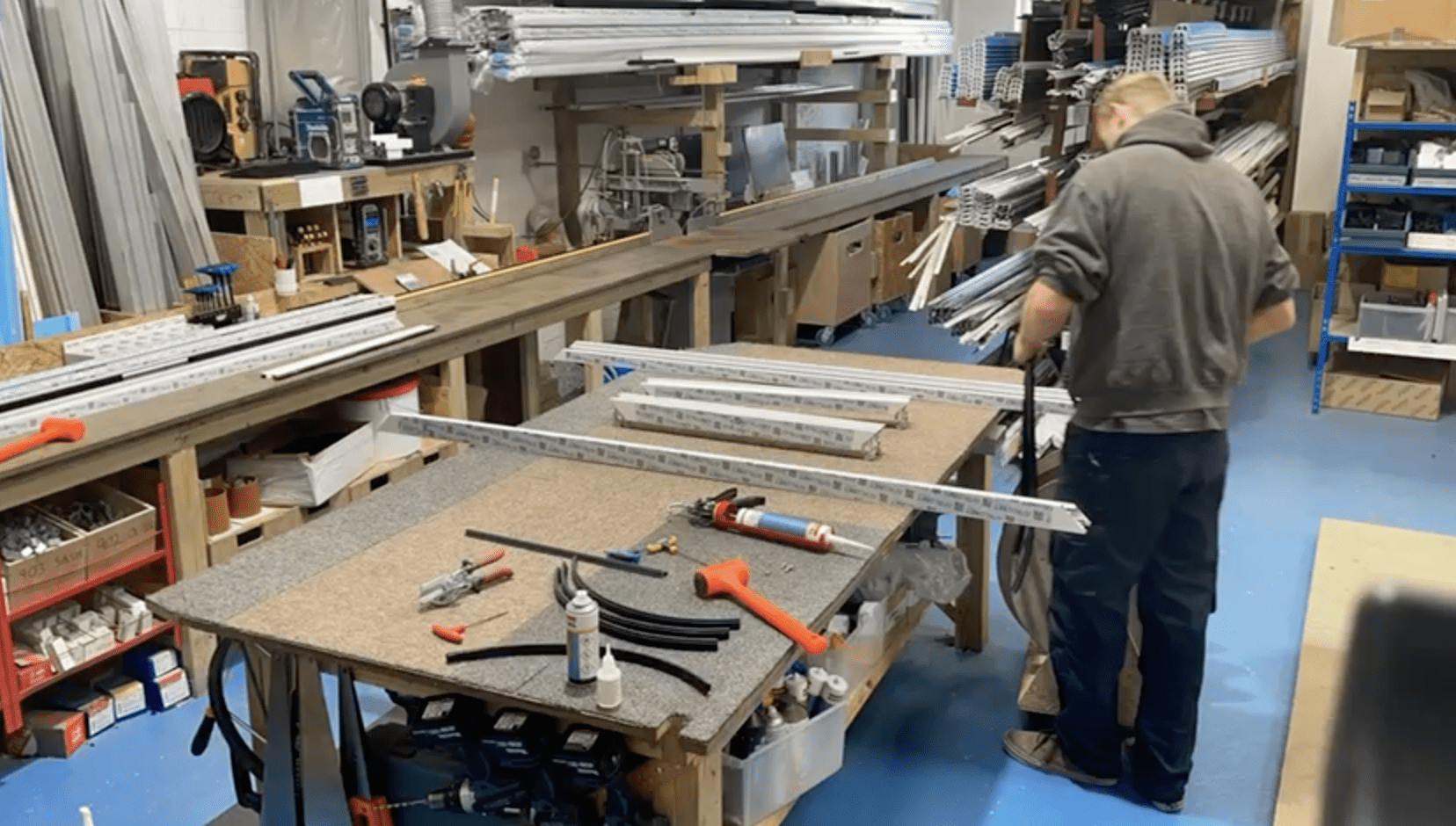

2. Fabrication & Quality Testing

In the second phase, the focus shifts to the actual fabrication of the frame. This is where the precise craftsmanship of our team comes to the forefront. Utilising traditional methods and modern machinery, the raw materials are transformed into the envisioned frame. This process is monitored to ensure that each step adheres to the predefined specifications, maintaining a balance between aesthetic appeal and structural integrity.

Quality testing is an integral part of this stage. Each frame undergoes a rigorous inspection process, evaluated against stringent quality standards. This includes checking for dimensional accuracy, material quality, and overall construction strength. Any discrepancies are addressed immediately, ensuring that the final product is visually stunning but also robust and durable.

3. Final Checks & Shipping

Once the frame fabrication and rigorous quality checks are completed, the next crucial step is the safe and efficient shipping of the frame parts. This stage involves careful packaging, ensuring that each component is securely protected to prevent any damage during transit.

We coordinate with reliable logistics partners to ensure timely and safe delivery to the client's specified location. Throughout this process, communication is key. We keep our clients informed of the shipping progress, providing tracking details and estimated delivery times.

trusted and reliable suppliers.